Industrial Metaverse: Is the future of the Digital Twins’ visualisation in 3D?

Digital Twins is one of those terms that captures your imagination. It has been massively popularised by sci-fi, where characteristics of specific physical objects are replicated and visualised in the real-time state of their virtual clones. So, it’s not a surprise that advances in the “alternative” realities (augmented, mixed and virtual) only help to bring sci-fi ideas to life.

The concept of digital twins is applicable to almost any industry: from healthcare (patient’s vital signs) and manufacturing (production line’s efficiency) to supply chain (cargo monitoring) and retail (out-of-stock control). As a result, you can keep your finger on the “pulse” of your digital twins’ source irrespective of its location, i.e. whether it’s next to you, on another continent or in an outer space.

Why:

If the digital twins can bring such unprecedented real-time insight, why are we not surrounded by them already in our daily job activities? The answer probably lies in their realisation.

There are many digital twins offerings out there in the market. However, it’s not that easy to implement them. Even after deployment, the scope of many digital twin solutions is often limited by the use of technical specialists only.

Taking this as a challenge, we have brainstormed it with my Microsoft Industry (Monika Zajc, Bob Williams) and Technology (Marius Cristian Ursu, Adrian Nicolae) colleagues on how possibly we can make digital twins solutions more appealing and re-usable on the CxO-level.

What:

As a target, we are looking here at a fictitious energy company that operates wind farms in remote onshore and offshore locations.

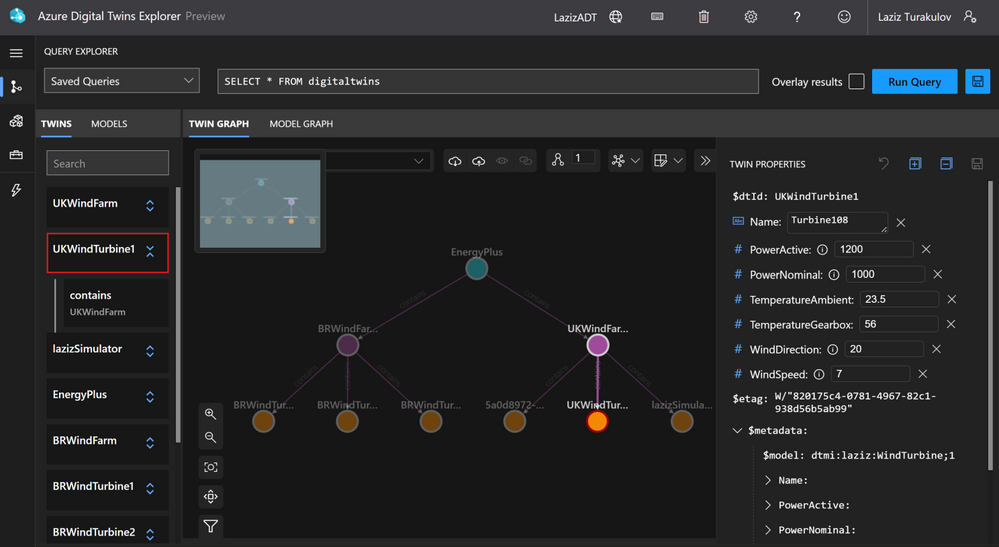

Technical support team wants to understand if the wind turbines’ performance is within the expected thresholds or requires some intervention, whether engineers can fix potential issues remotely or if an operator has to dispatch somebody for on-site maintenance, etc. For this part of the business scenario, the use of the digital twins is a no-brainer and an engineering team can obtain required details from the digital twins’ graph as shown below.

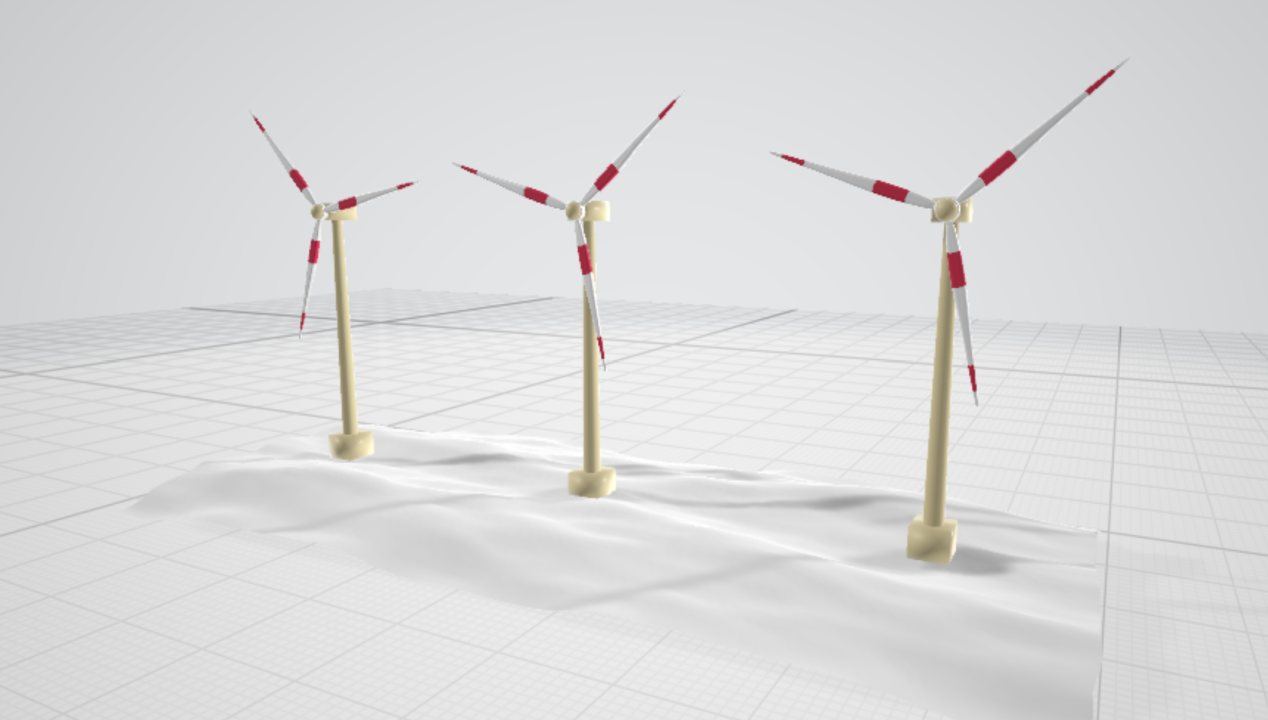

Interestingly, the same information can be mapped to the visual components in 2D (charts) and 3D (representative models of each turbine) space. Now, without specialised engineering degree, you can easily identify that one of selected wind turbines is overheating and this may lead to a potential issue.

Moreover, we can bring such 3D-enabled digital twins all the way up to the boardroom level, so that CxO get a bird’s eye view of their geographically spread enterprise. Using our fictitious example, company directors can see in real time how performance of a wind farm in region X is reflected in the target KPIs (key performance indicators) or if forecasted weather changes impacted supply in region Y. This can be adapted to any specific business scenario and audience.

How:

If you are sold on the idea of 3D-enabled digital twin, the next logical question is how implement it? And it turns out to be a not-so-complex task.

- Azure Digital Twins’ functionality has been recently enhanced with a new 3D Scene capability. So, you can bring now your own 3D model and integrate it with the existing digital twins graph;

- I personally used open-source Blender platform to model and animate 3D scene with those three wind turbines. You can use any other 3D platforms of choice;

- Real-time telemetry has been generated by the Seeed Studio’s SenseCAP K1100 (the sensor prototype kit with LoRa and AI) and delivered to Azure cloud via LoRaWAN connectivity;

- Finally, additional mock telemetry for the wind turbines scenario has been generated via Python simulator.

Video of a working end-to-end solution can be found here. And if you want to find additional technical content on the Internet of Things (IoT), you may explore these Discussion Spaces on the Microsoft Tech Community. Thank you!

Disclaimers:

- As a Microsoft employee, I used only publicly available software and hardware components for the above prototype development;

- SenseCap K1100 kit has been provided by Seeed Studio as a free hardware for the “IoT Into the Wild Contest for Sustainable Planet 2022”.

Published on:

Learn more